Jefferson Lab startup to create stronger-than-steel polymer

A super fiber developed by Jefferson Lab in Newport News is about to take on a public persona. BNNT LLC plans to start producing the fiber, known as Fibril Boron Nitride Nanotubes (Fibril BNNT), by next spring at a 3,500-square-foot factory in Newport News. With potential uses in spacecrafts and golf clubs, BNNT isn’t marketing the product as a one-trick pony. “It’s a unique product that has potential impact in a broad scale of product areas,” says R. Roy Whitney, the company’s president and CEO.

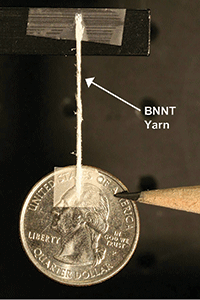

Fibril BNNT looks like cotton but is

strong enough to be used in

jet engines.

BNNT LLC describes its product as a “super-strong, heat-resistant, textile-like polymer with the appearance of cotton, but a molecular backbone 100 times stronger than steel.” That means application areas could include armor, jet engines or cancer therapies.

Fibril BNNT could be used, for example, to lower the weight of tennis rackets while still giving them strength and flexibility. It could also provide high-temperature ceramics that do not crack, for use in jet and rocket engines.

The material was developed at Jefferson Lab, where Whitney has served as chief information officer/chief technology officer. He now is on leave to spearhead BNNT LLC.

“They are excited and understand the potential and are supportive that we succeed, which is great,” Whitney says of Jefferson Lab. NASA Langley Research Center and the National Institute of Aerospace in Hampton collaborated on the development of Fibril BNNT. The Defense Advanced Research Projects Agency in Arlington also supported the project.

BNNT LLC is investing up to $4 million in the venture and creating 20 jobs, Whitney says. So far, response from potential clients has been good:

“They’d like to get their hands on the material,” Whitney says, noting that currently only 10 grams of Fibril BNNT (about the weight of four pennies) exist. BNNT LLC wants to “have a commercial scale of production which will be many times that” and sell it to interested customers, Whitney says.

The company is hoping to attract customers in the nanotube materials sector, a rapidly growing industry generating more than $1 billion per year in revenue. Possible applications for nanotubes range from use in computer chips, because they can conduct electricity, to the field of medicine, where nanotubes hold the potential to help fight cancer and other diseases.

BNNT LLC says that unlike the better-known carbon nanotubes, Fibril BNNT is more heat-resistant and is easier to synthesize in a high-quality form. “It’s not just one thing for one product,” Whitney says.

to be broadly impactful.”

s