Farmbots in the fields

Virginia Tech’s robotic innovations connect to the university’s agricultural roots

Tim Thornton //July 27, 2018//

Farmbots in the fields

Virginia Tech’s robotic innovations connect to the university’s agricultural roots

Tim Thornton //July 27, 2018//

With all the news coming out of Virginia Tech about burrito-delivering drones, self-driving vehicles and autonomous underwater craft, it’s easy to forget the university began as, and continues to be, an agricultural school. As incongruous as it may seem, robotics and agriculture often overlap, and innovations emerging at that intersection are almost certain to grow.

Associate Professor Alexander Leonessa, for instance, advised two student teams who collaborated to win the 2018 agBOT Challenge, a national competition to see whose robot can best perform an agricultural task.

The challenge in this year’s competition was to create an autonomous watermelon-harvesting machine. One of the Virginia Tech teams concentrated on getting the harvester in place. The other focused on evaluating and harvesting the melons. The resulting collaborative system had to perform on its own.

“This was about creating an autonomous harvesting system, with the emphasis on being autonomous,” Leonessa says. “So, there was no human interaction. You push a button, and the thing goes and finds the watermelons, decides if they are ripe, and, if they are, picks them up.”

The winning watermelon harvester is a two-part system. An ATV equipped with sensors finds the watermelons and positions the harvester so it can place each melon into a trailer.

But first, the harvester has to be sure the watermelon is ripe. It makes that decision the same way many people do — by thumping the melon and listening for a deep, hollow sound. The harvester slaps each melon and measures the resulting sound against a frequency range ripe watermelons generally produce.

“We placed a microphone under the unit and angled it to the bottom of the melon where it captures the reverberations from the slapper,” the teams’ leader, Hongxu “Howard” Guo, a double major in mechanical and electrical engineering, said in a release describing the project. “If the audio analysis indicates a sound ratio above a particular threshold, what we call the sub-band short-time energy ratio, then the watermelon is ripe and harvested. If not, it is left on the ground.”

The system’s design was the result of a four-month process, Leonessa says. Students considered several options, including using a robotic arm to lift the melons into the trailer. That option was complicated and expensive. The final version, Leonessa says, is relatively inexpensive, while being easy to use and maintain.

It’s also successful, winning the contest’s top prize of $30,000. That money will go toward next year’s agBOT Challenge and other projects, Leonessa says.

He says that while he would entertain proposals to commercialize the watermelon harvester, that’s not really the point of the project. It was a senior project in a two-semester class that gives undergraduates a chance to prove they can design, develop and build a prototype that will solve a problem.

“For me, it was more of a teaching project,” Leonessa says. “My career as a watermelon harvester has pretty much come to an end.”

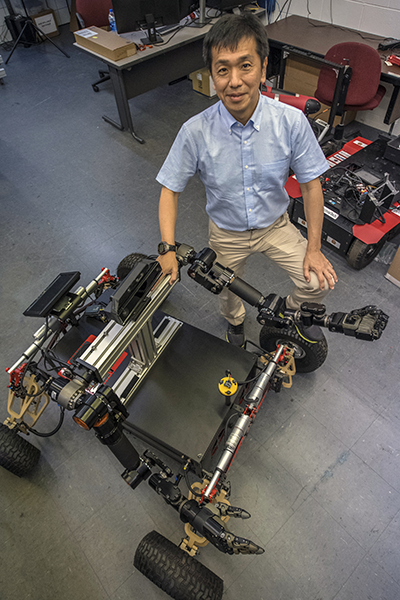

Grape harvester

People have been trying to build such a harvester for decades, but they’ve never succeeded, says Professor Tomonari Furukawa, the project leader. The problem, he explains, is two-fold. Technology hasn’t been up to the complicated task, and researchers were aiming too high. Time and research may have solved the first problem. A change in approach may have taken care of the second.

“In the past, the robotics people have been always trying to develop automatic harvesters,” Furukawa says. “Many people have made a mistake, as I mentioned, simply because they were too ambitious … We don’t try to be ambitious. It’s an assistive approach … We don’t try to fully automate. Rather, we try to make an assistive robot that uses human capabilities.”

Instead of replacing humans with an autonomous picker, Furukawa and Mahindra aim to make humans better at the job. “We minimize the motion and the other effort that the human needs to put in, including perception,” Furukawa says. “That way, the humans feel less fatigue.”

That assistance makes humans more efficient pickers. “Their aim is quality management,” Furukawa says of Mahindra, “because human quality management is very subjective and cannot be controlled.”

Some human pickers may exercise good judgment about which grapes are ready to harvest and which are not. “It depends on the harvester,” he says. By using image sensors and other measuring equipment, “the robot doesn’t make a mistake. The robot is much more consistent.”

Picking grapes is particularly challenging for a robotic arm. Grapes are small and soft. Their sizes and shapes vary. So, the harvester must be versatile. Once the machine masters grapes, it may open the way to other crops. “We want to learn from grapes,” Furukawa says, “and we want to move on to other agriculture products as well.”

Furukawa doesn’t want to guess how long he and his team of doctoral students will be working on the grape harvester, but he says the timeline will probably be measured in years.

“We don’t want to say it. It just gives us pressure,” he says. “As the research goes, we will develop a roadmap to commercialization.”

Wearable robotics

Another project aiming for commercialization is a three-year study funded by an NSF Partnership for Innovation grant that explores how assistive, wearable robotics might help farmers work longer and more efficiently while avoiding wear on their bodies.

“In Virginia, the average farmer’s age is about 65, which means decades of hardship and hard work,” Leonessa says. ”This is really taking a toll on the farmers and their bodies.”

His team plans to develop assistive robotics — ranging from knee braces to exoskeletons — to reduce that toll. The devices will provide stability and support, but they will also give farmers additional strength. They may allow farmers to handle their daily tasks more easily so that they can continue to work years longer.

“Some think they’re trying to make farmers work forever,” Leonessa says. “That is not our intention.” The goal of his project is to relieve farmers “of some of the hardship of the work so they can age gracefully and come out at 65 with their body fully functional rather than being deteriorated by a lifetime of hard work.”

Because of the hard work and the large investment new farming operations require, fewer people are interested in farming as a career. Therefore, improving farmers’ efficiency, endurance and health are increasingly important.

The project is recruiting farmers now. Participants will visit a physical therapist to see what kinds of apparatus might benefit them. Leonessa’s team will outfit the farmers, who will go back to the physical therapist to make sure everything seems to be working as it should. Then farmers will head out into the field, and researchers will evaluate the robotics’ efficacy.

While a farmer in wearable robotics might sound like a plot element in a sci-fi novel, Leonessa points out that futuristic technology already is embedded in modern agriculture. Farmers use drones and GPS devices to help them decide when and where to plant, water and fertilize their crops and also when and where to apply pesticides and herbicides. There’s no reason to think technology’s role won’t continue to grow.

“I tell my students, I look forward to the day when, to be a farmer, you need a degree in computer science,” he says.

Leonessa is half-joking when he says that. But only half.

t